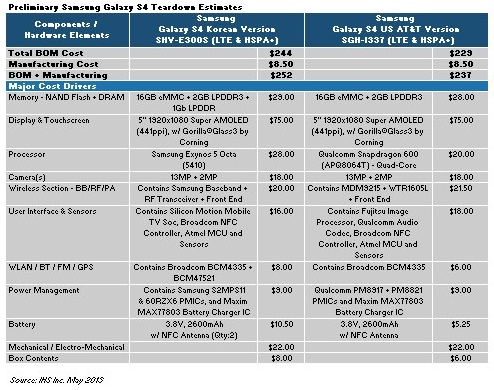

After mega success of Samsung Galaxy S3 the launch of high-profile Galaxy S4 was received with great enthusiasm by both media and consumer. The phone currently retails around $700 to $800 but closer look of its component after a tear down reveals that the Korean company has used most of the components that it produced locally from its subsidiaries. It might be of great interest for people to know the cost incurred to make a single Galaxy S4 smart phone. A recent complete teardown analysis conducted by market research firm IHS has revealed some amazing revelations regarding the actual cost of the phone. The actual cost of Galaxy S4 is around $237 which is a bit higher when compared to $205 of Apple iPhone 5 with 16 GB version. Even the cost for making Lumia 900 comes around $209, which is lower. But incidentally the cost of S4 is lower than that of Samsung’s Galaxy Note tablet, which according to IHS cost around $270 to make. Most of the top phone manufacturer source their component form various suppliers but Samsung with diversified business has a capability to supply itself many key component. But the galaxy S4 which is currently sold in US has snapdragon processor which is supplied by Qualcomm this adds extra $20 for the making of S4. Samsung is known to make four versions of phone for different regions of the world. Two are sold in US with different carriers one with AT&T and T-Mobile and other with Verizon Wireless and Sprint. The flash memory which is used to store data in S4 is also supplied by Samsung.

After mega success of Samsung Galaxy S3 the launch of high-profile Galaxy S4 was received with great enthusiasm by both media and consumer. The phone currently retails around $700 to $800 but closer look of its component after a tear down reveals that the Korean company has used most of the components that it produced locally from its subsidiaries. It might be of great interest for people to know the cost incurred to make a single Galaxy S4 smart phone. A recent complete teardown analysis conducted by market research firm IHS has revealed some amazing revelations regarding the actual cost of the phone. The actual cost of Galaxy S4 is around $237 which is a bit higher when compared to $205 of Apple iPhone 5 with 16 GB version. Even the cost for making Lumia 900 comes around $209, which is lower. But incidentally the cost of S4 is lower than that of Samsung’s Galaxy Note tablet, which according to IHS cost around $270 to make. Most of the top phone manufacturer source their component form various suppliers but Samsung with diversified business has a capability to supply itself many key component. But the galaxy S4 which is currently sold in US has snapdragon processor which is supplied by Qualcomm this adds extra $20 for the making of S4. Samsung is known to make four versions of phone for different regions of the world. Two are sold in US with different carriers one with AT&T and T-Mobile and other with Verizon Wireless and Sprint. The flash memory which is used to store data in S4 is also supplied by Samsung.

IHS estimates 16GB of memory increased the cost by $28. Other component supplied by Samsung included camera module and some wireless baseband chips, touch screen parts etc.

Source: http://goo.gl/TFcyt